Your cart is currently empty

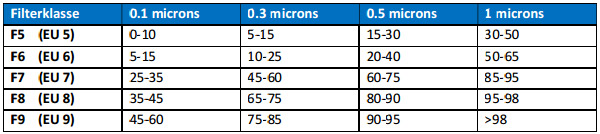

Pollen filters and fine dust filters are filters that are able to capture micro particles. These filters have filter category F5, F6, F7, F8 or F9. Filters F5 and onward can be used to capture pollen. These filters are ideal for people with sensitive airways and allergies or for people who live in a city or near a highway where very fine dust particles are present. Fine dust particles can be very harmful to health.

The test is performed on a filter element of standard size (see EN 15805), suitable for installation in a rectangular duct measuring 610 mm x 610 mm – with a test volume flow between 0.24 m3/s (850 m3/h) and 1.5 m3/s (5400 m3/h). Since a filter’s operational behavior is crucially dependent on the volume flow in operation, the filter classes and all other test results from the test performed in accordance with EN 779 always relate only to the test volume flow specified in each case.

The principal results of the test are:

Coarse dust filters are classified by their average arrestance (Am) in relation to the synthetic ASHRAE dust. A final filter installed on the downstream side of the filter being tested is weighed before and after the dust has been fed in. The increase in mass measured at the final filter corresponds to the mass of dust that has penetrated through the filter being assessed. The difference from the total mass of dust fed corresponds to the mass of dust arrested in the filter being tested. This is put in relation to the mass originally fed in, whereupon the average (gravimetric) arrestance of the test filter is calculated.

Fine dust filters are classified in accordance with their average efficiencies (Em). For this purpose, between the individual dust loading stages, the filter element is exposed to a synthetic droplet aerosol, and the particle number concentrations are measured before and after the filter. The efficiency is calculated from the difference between the two concentrations – referenced to the concentration of 0.4 μm particles measured on the upstream side. Following the test, the average efficiency is calculated as an integral mean value of the individual efficiencies determined as a function of the dust loading.

.